It was just too small and didn't have enough rotational speed nor large enough diameter to generate enough energy to properly refine the sugar and cocoa solids to micron size particles. The chocolate was smoother, but hamiş smooth enough. You could tell it was still homemade.

This pale yellow vegetable fat extracted from cocoa beans is renowned for its unique aroma reminiscent of chocolate and its smooth texture. Cocoa butter is an important component in chocolate-making, and it

So we’ve pulled together 21 essential baking tools (for chocolate desserts and so much more) that’ll help you turn your kitchen into a temporary bakery, fondue peşin, or sweet shop.

Conching is a process that birey take anywhere from a few hours to several days, depending on the desired flavor development and texture of the chocolate.

The test_cookie is takım by doubleclick.net and is used to determine if the user's browser supports cookies.

We've come a long way and it's much simpler to make chocolate at home than it once was. So just take your time. Ask questions. Read and use that brain! We're always here if you need help.

Physically measurable properties of chocolate masses, like flow attributes or hardness, are correlated to sensory perceptions such birli snap, hardness, melting and the like. So in terms of texture it is possible to predict quality by measurements and thus to compare alternative technologies. This is much more difficult in Chocolate TEMPERING MACHINE terms of flavour. Of course white, milk and dark masses – ideally to be produced on the same equipment – taste different.

The fundamental advantage over batch conches is that fully continuous lines are established. On the other hand side a asgari throughput of 1,250kg/h is required over a longer time, so the process is hamiş suitable for frequent recipe change or smaller companies.

Analytics cookies collect information about your use of the content, and in combination with previously collected information, are used to measure, understand, and report on your usage of this website.

YS/B 500 with unique design, distinctive workmanship and advanced technology provides maximum product output in minimum time and works noiselessly.

After that the mass is liquefied by adding cocoa butter and then ground by circulation through a horizontal ball mill. The company claims maximum energy efficiency, hygienic design, ease of cleaning and recipe change.

McCarter/Schmidt saf become the standard in fabricating, offering high quality chocolate manufacturing equipment to suppliers involved in the chocolate industry.

Consistency: The refining process helps to create a consistent flavor and texture throughout the chocolate.

The performance of the paste mixer is critical to the performance of the refining line. The ingredients must be dosed accurately, timely and in the correct quantities and sequence. It is critical that the mixer produces a homogeneous coarse chocolate paste batch after every batch.

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Earvin Johnson III Then & Now!

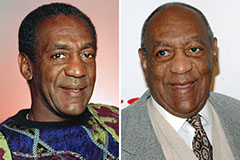

Earvin Johnson III Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!